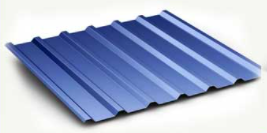

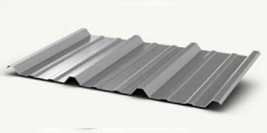

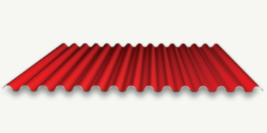

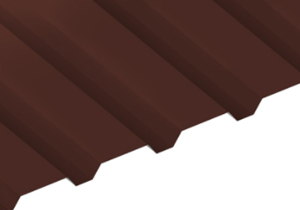

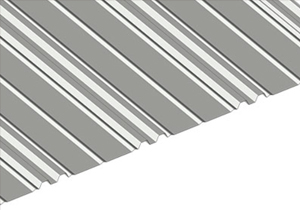

Corrugated metal roof panels are made of high-quality steel and feature a corrugated pattern for added strength. This makes corrugated metal roofing panels suitable for factories, barns and stables, as well as commercial and agricultural buildings.

They are also relatively light compared with other roofing systems, which makes them ideal for various residential projects. These projects include garage roof replacements, shed replacements, and more.

Corrugated metal roofs can last for decades due to their hardened steel construction and optional plastic coating.

In addition, they are nearly maintenance-free. Corrugated metal roof panels are ideal for farmers or business owners without much time to deal with roof maintenance.

They are also a perfect choice for those who want to protect valuable items in their barn or garage.

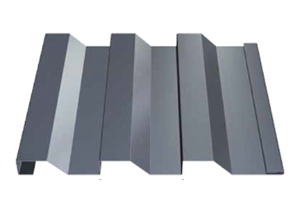

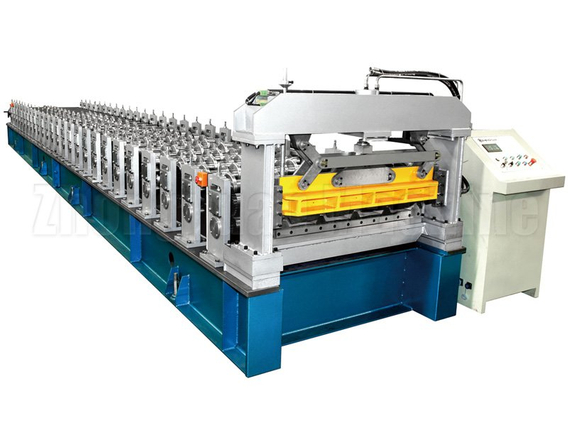

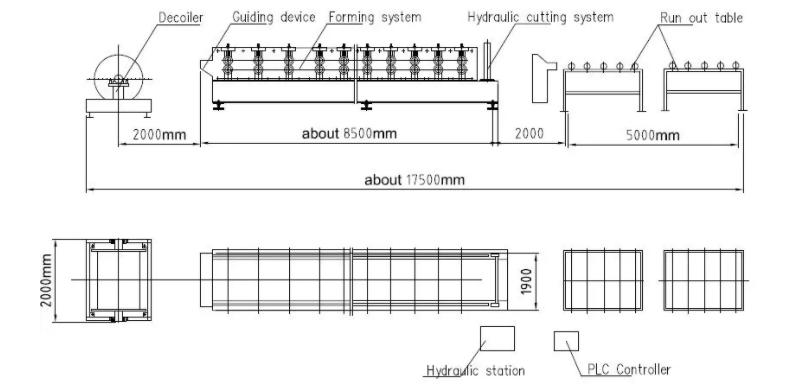

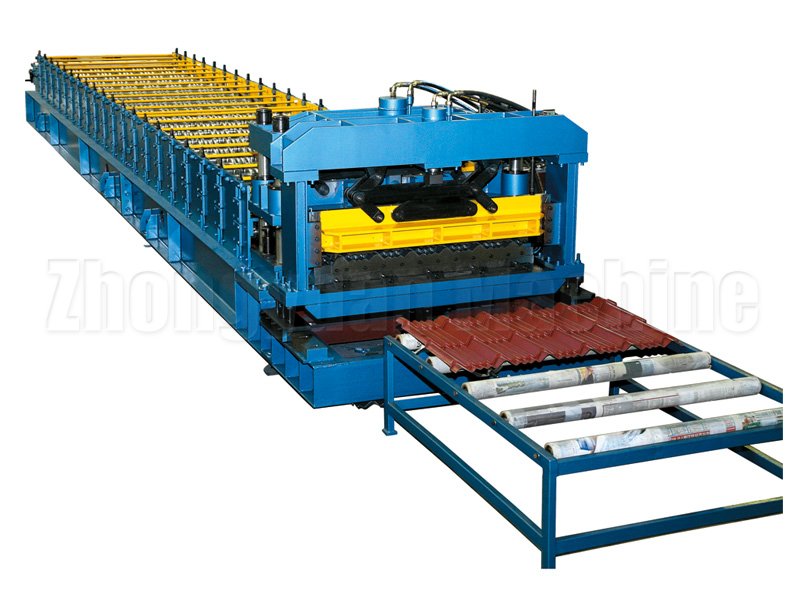

Corrugated Roof Panel Roll Forming Machine A corrugated sheet roll forming machine is a system for producing corrugated metal roofs and wall panels, which have been used around the world for several years. Contractors and homeowners like them because they are stronger, have more structural advantages, and look better. These panels are often used in residential construction.

Corrugated metal panels can be used as wall panels as well as roofing shingles. Due to the widespread use of corrugated sheets, corrugated roofing roll former are among the top metal roll forming machines.

You may want to start a roofing plant or a project for corrugated sheet roofing roll forming machine, please check the details here:

https://www.zhongyuanforming.com/Corrugated-Roll-Forming-Machine-Aluminium-Long-Span-Corrugated-Sheet-Making-Machine-pd6837772.html Or if you want to save your time, money, and space, check out this remarkable machine:

https://www.zhongyuanforming.com/America-AG-Rib-Profile-Double-Layer-Machine-pd6017772.html  English

English