- HOME

- ABOUT US

- ROLL FORMING MACHINE

- Step Tile Roll Forming Machine

![1-Step-Tile-Roll-Forming-Machine.jpg]()

- Metal Sheet Roll Forming Machine

![2Metal-Sheet-Roll-Forming-Machines.jpg]()

- Double Layer Roll Forming Machine

![3-Double-layer-roll-forming-machine.jpg]()

- Purlin Roll Forming Machine

![4-Purlin-roll-forming-machine.jpg]()

- Metal Deck Roll Forming Machine

![5-Metal-deck-roll-forming-machine.jpg]()

- Sandwich Panel Roll Forming Machine

![7-Sandwich-panel-roll-forming-machine.jpg]()

- Guardrail Roll Forming Machine

![6-Guardrail-Roll-Forming-Machine.jpg]()

- Gutter Roll Forming Machine

![Half-Round-Gutter-Roll-Forming-Machine.jpg]()

- Standing Seam Machine

![Standing-seam--machine-9.jpg]()

- Sigma Forming Machine

![10-Sigma-forming-machine.jpg]()

- Cable Tray Roll Forming Machine

![Cable-tray-roll-forming-machine.jpg]()

- Stud and Track Forming Machine

![Stud-and-Track-Forming-Machine-12.jpg]()

- Shutter Door Forming Machine

![Shutter-door-forming-machine-13.jpg]()

- Supplementary Machine

![14-Supplementary-machine.jpg]()

- Step Tile Roll Forming Machine

- APPLICATION

- SHIPMENTS

- NEWS

- CONTACT US

Specialized in One-Stop Solutions for Metal Deck Roll Forming Machine

"All-in-house source"– from raw material to the final high-precision forming machine.

All are done in our factory. Quality and delivery time can be controlled here.

All are done in our factory. Quality and delivery time can be controlled here.

With technical support by our 20 years experienced engineers and technicians,

we can provide you suggestion and solution within 24 hours.

we can provide you suggestion and solution within 24 hours.

Our Metal Deck Roll Forming Machine are well installed and tested before delivery.

You only need to connect some tubes and wires in your factory.Video and manual will show you how to do.

Our experienced technicians can go to your factory and train your workers.

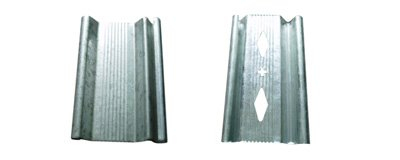

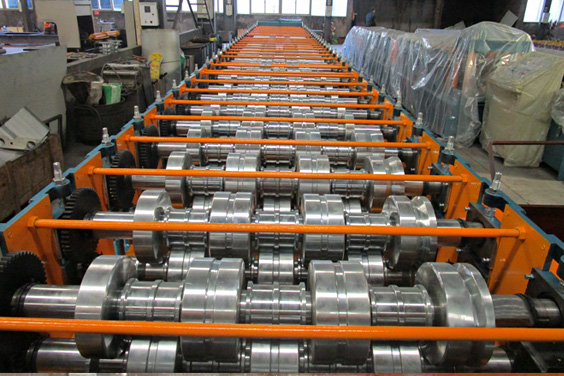

Our Metal Deck Roll Forming Machine's Advantages

【Forming Speed】18-20m per minute.

【Anti-rust Roller】CNC machine tooled, Plated with 0.05mm hard chrome .

【Heat Treatment】Heat treatment for cutting frame to remove the steel stress, to avoid deformation.

【Cutter blade】Cr12 mould steel with quenched treatment, long life time.

【High Precision】Shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance.

【People Originate】Introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction.

【Excellent Services】Technician can be sent to your factory to install the machine and train your workers. Engineers are able to service overseas.We supply lifetime services for our machines.

【Anti-rust Roller】CNC machine tooled, Plated with 0.05mm hard chrome .

【Heat Treatment】Heat treatment for cutting frame to remove the steel stress, to avoid deformation.

【Cutter blade】Cr12 mould steel with quenched treatment, long life time.

【High Precision】Shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance.

【People Originate】Introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction.

【Excellent Services】Technician can be sent to your factory to install the machine and train your workers. Engineers are able to service overseas.We supply lifetime services for our machines.

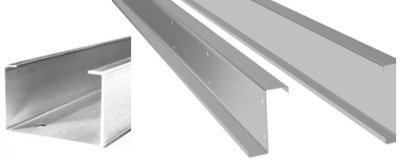

Technical Data of Decking Roll Forming Machine

| Suitable material | Q235 color steel sheet;0.8-1.2mm, |

| Forming speed | about 18-20m/min |

| Power Requirement | Main motor power: 11X2 Kw(Depend on final design) |

| Hydraulic station power: 5.5Kw(Depend on final design) | |

| Material of forming rollers | No.45 steel, plated with chrome on surface. |

| Material of cutter | Cr12 mould steel with quench treatment, HRC58-60 |

| Material of shaft | High quality 45# steel with heat treatment. |

| Roller grinder milling. | |

| Shaft diameter | 82mm |

| Controlling system | Mitsubishi PLC & converter |

| Total weight of machine | About 16500KGS |

| Machine’s size | about 26m×1.8m× 1.5m (Depend on final design) |

| Shipping | 1x40GP and 1X20GP containers can load one machine |

Automatic & Easy Operate

Machine long life: Roller material is high grade No.45 forged steel,plated with hard chrome,processed by digital-controlled procession.

Mitsubishi PLC with touch screen. Friendly man-machine interaction.The system is simple to learn and easy to operate.

Automatic Operation:once you set quantity and length of product,machine will produce product automatically.

Mitsubishi PLC with touch screen. Friendly man-machine interaction.The system is simple to learn and easy to operate.

Automatic Operation:once you set quantity and length of product,machine will produce product automatically.

Metal Deck Roll Forming Machine Video

“All-in-house source” – from raw material to the final high-precision forming machine.All are done in our factory.

Quality and delivery time can be controlled here.

With technical support by our 15years experienced engineers and technicians, we can provide you suggestion and solution within 24 hours.

We guarantee lifetime services for our machines.

Simple to install and easy to maintain. Our machines are well installed and tested before delivery. You only need to connect some tubes and wires in your factory. Video and manual will show you how to do.Our experience technicians can go to your factory and train your workers.

Quality and delivery time can be controlled here.

With technical support by our 15years experienced engineers and technicians, we can provide you suggestion and solution within 24 hours.

We guarantee lifetime services for our machines.

Simple to install and easy to maintain. Our machines are well installed and tested before delivery. You only need to connect some tubes and wires in your factory. Video and manual will show you how to do.Our experience technicians can go to your factory and train your workers.

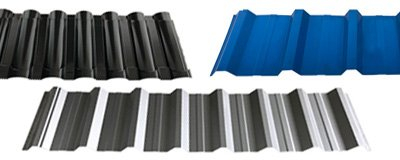

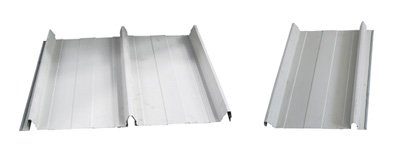

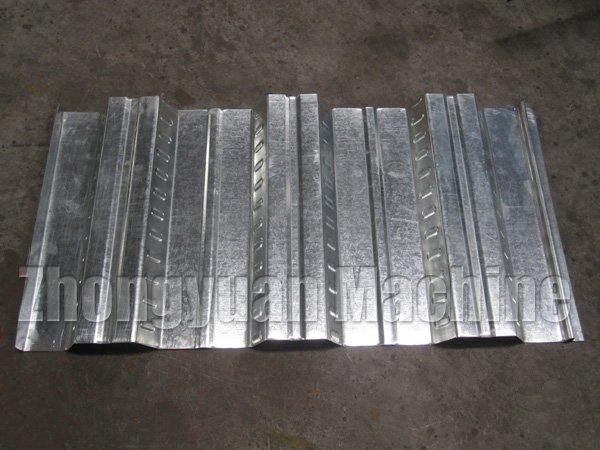

Metal Deck from Metal Deck Roll Forming Machine

Product application: The metal deck produced by floor deck forming machine is used as decking of building; It has high strength with big wave length. It adheres well to concrete. Used on high building, it not only saves steel mold plate, but also reduces the weight. With the same bearing capacity, it economized steel and cuts down investment accordingly.

Why Choose Us

Beginning 2003

Zhongyuan Machinery is experienced manufacturer of metal forming machinery...

Certifications

We have rich experience for metal forming machine solution,competitive pricebook...

Custome trust

Today, we have exported our machines to America, Chile, Mexico, Bolivia, Brazil,Indonesia,India, Russia...

The Workflow of Processing Workshop

For more metal deck roll forming machine information, get best price.

Please do not hesitate to send your detailed inquiries to us.

Hangzhou Zhongyuan Machinery Factory

Add: No.228, Yongli, Nanyang Street, Xiaoshan District, Hangzhou City, Zhejiang, P. R.of China.

Tel: 0086-13867521382

E-mail: zhongyuanforming@hotmail.com

Tel: 0086-13867521382

E-mail: zhongyuanforming@hotmail.com

Custom Roll Forming Machine

Custom Roll Forming Machine | Metal Deck Roll Forming Machine | Sandwich Panel Production Line | Step Tile Roll Forming Machine | Metal Sheet Roll Forming Machines | Stud and Track Forming Machine | Double Layer Roll Forming Machine | Purlin Roll Forming Machine | Metal Deck Roll Forming Machine | Guardrail Roll Forming Machine | Gutter Roll Forming Machine | Standing Seam Machine | Shutter Door Forming Machine

Copyright © 2003-2018 Hangzhou Zhongyuan Machinery Factory All Rights Reserved