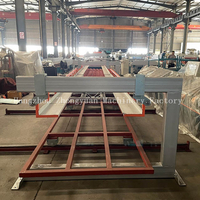

Layout Drawing of Custom Roll Forming for Step Tile

![]()

We are committed to producing high quality machinery:

Roll Forming System

Roller material is high grade No.45 forged steel plated with hard chrome, by digital- controlled procession.

![roll forming system roll forming system]()

Hydraulic Pressing Device

![Hydraulic-pressing-device.jpg Hydraulic-pressing-device.jpg]()

High Accuracy

1、Shaft material is No.45 steel with diameter 72mm, strong and durable.Shafts for rollers are tooled by grinding machine 2 times. Ensure product accuracy.

2、Finished shafts from grinding machine,rollers on these shafts can ensure final sheet accuracy.

![roll forming high accuracy roll forming high accuracy]()

High Efficiency

Hydraulic system,Designed with accumulator to accumulate energy and cooling fan to cool hydraulic system, so that ensure the machine can run to produce 6m per minute stably. 2880m per shift one day(8 work hours).

![High Efficiency High Efficiency]()

Automatic & Easy Operate

Machine long life: Roller material is high grade No.45 forged steel,plated with hard chrome,processed by digital-controlled procession.

Mitsubishi PLC with touch screen. Friendly man-machine interaction.The system is simple to learn and easy to operate.

Automatic Operation:once you set quantity and length of product,machine will produce product automatically.

![Automatic-Easy-Operate Automatic-Easy-Operate]()

Control Quality Well

Zhongyuan factory is a "All-in-house source" from raw material to the final high-precision forming machine. All are done in our factory. Quality and delivery time can be controlled here.

Simple to install and easy to maintain.

You only need to connect some tubes and wires in your factory. Video and manual will show you how to do.

Our experienced technicians can supply overseas service.

English

English